From Ingredients to Indulgence: Unveiling the High-Tech Craft of Doughnut Production

Introduction

Doughnuts are more than just a delicious treat; they’re a global phenomenon with a rich history and a significant presence in the food industry. In this post, we’ll take a closer look at how these beloved pastries are made on an industrial scale, revealing the technology and techniques that produce your favorite morning indulgence.

The Ingredients

The journey of a doughnut begins with its ingredients. At the core, most doughnuts contain:

- Flour: The backbone of any doughnut, providing structure.

- Sugar: For sweetness and color during cooking.

- Eggs: To bind the ingredients and add richness.

- Milk: Adds moisture and flavor.

Yeast or Baking Powder: Yeast for raised doughnuts, creating a light and airy texture; baking powder for cake doughnuts, yielding a denser, tender crumb.

Flavorings: Vanilla, cinnamon, and nutmeg are common, but the possibilities are endless.

High-quality ingredients are essential for taste and texture. Manufacturers often source premium ingredients to ensure consistency and flavor.

Mixing and Kneading

To craft the dough, blend the dry and wet components until a uniform mixture forms. For yeast doughnuts, it’s crucial to mix gently to prevent excessive gluten development, then knead to build the gluten network vital for the dough’s elasticity and the final product’s satisfying chewiness. The ideal tool for this task is the Topos Open Frame Removable Bowl Spiral Mixer. Designed for durability and heavy production demands, it also excels in hygiene. This mixer adeptly manages large-scale production requirements, ensuring the creation of exceptional yeast doughnut dough.

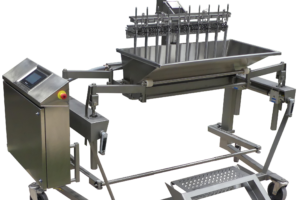

Forming

After the dough is mixed and kneaded, it’s transformed into iconic doughnut shapes, often achieved with a dough sheeter and cutters for yeast doughnuts to ensure even thickness before cutting into rings. Cake doughnuts are typically shaped using a depositor that directly forms the batter into rings pre-cooking. The industry has long relied on mechanical depositors, but now, Topos Mondial introduces a modern twist with its Digital Depositor. This cutting-edge device epitomizes the merger of digital precision with traditional doughnut crafting, offering unparalleled automation and accuracy, marking a new era for bakeries globally with its digitally controlled operation.

Proofing and Resting (Yeast Doughnuts)

During the proofing stage, yeast doughnuts are given time to rise, a critical process for achieving a light, airy texture. This involves resting the dough in a warm, moist setting, facilitating yeast fermentation and dough expansion. Topos Mondial’s TFP final proofers, designed with single or dual climate-controlled zones, ensure optimal results across a variety of products. Their modular design allows for customization in height and length, accommodating specific production needs and spatial constraints, thus optimizing the proofing process for quality and efficiency.

Cooking

Doughnuts are typically fried or baked. Frying, the traditional method, gives a crispy exterior and soft interior, with commercial fryers like Topos TGF ensuring uniform cooking through precise temperature control, flights to navigate the doughnuts through oil, and a turner for an even crust. Baking offers a lighter texture and is a healthier option, gaining popularity among health-conscious consumers for its distinct taste and feel.

Glazing and Topping

After cooking, doughnuts are often glazed or topped. Glazes range from simple sugar solutions to flavored icings like chocolate or maple. Toppings can include sprinkles, sugar, crushed nuts, or even bacon bits. Automation ensures each doughnut is evenly coated, maintaining quality and consistency across the batch.

Packaging and Distribution

Once glazed and cooled, doughnuts are packaged for distribution. Packaging is designed to protect the doughnuts during transport while maintaining freshness. Innovations in packaging technology help extend shelf life without compromising quality.

Challenges in Doughnut Manufacturing

Doughnut manufacturers face several challenges, including maintaining consistency across batches, ensuring food safety, and reducing waste. Solutions involve rigorous quality control, adherence to food safety standards, and adopting sustainable practices in production and packaging.

Conclusion

The industrial manufacture of doughnuts is a fascinating blend of art and science, involving precise techniques and innovative technologies. Next time you enjoy a doughnut, take a moment to appreciate the complex process behind its creation.