Topos Mondial can now offer a Load Master Proofer Automatic Loader. The automatic loading provided by the shuttle box not only eliminates misaligned product, drastically reducing downtime, but also prevents the operator from having to spend as much time and energy on proofer loading. This means that the Topos Proofer can be safely and easily loaded using less manpower. On top of that, work injury probability is greatly reduced over time.

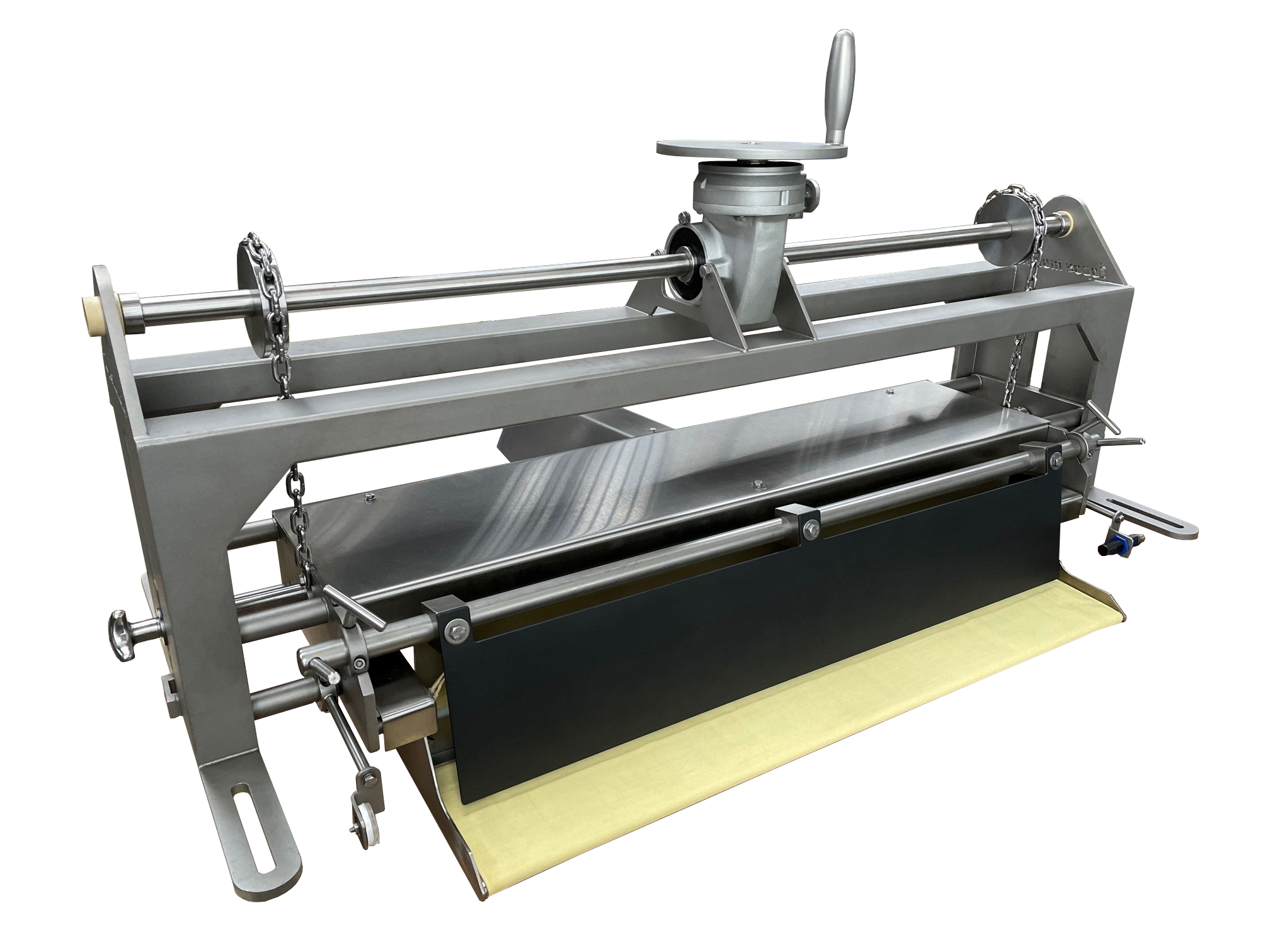

Model LM-850 has an 850 millimeter tray which allows for 8 doughnuts in a row, at a time. Similarly, LM-1000 has a 1000 millimeter tray which allows for 10 doughnuts in a row, at a time. Both Models contain fully adjustable ambidextrous on-the-fly controls, for left and right-handed operator working positions. Easy maintenance, heavy duty construction and super sanitary design are all pro-components of this product.

It has an automatic mode and a hand-loading mode. When in automatic mode, the sheeting machines are on and the conveyor functions as a bridge. When in hand-loading mode, the sheeting machines are off. The conveyor has two people taking doughnuts and placing them between the lines on the hand-loading conveyor.

Made by: Topos Mondial Corp

Quantity Available: Made to order

Request a Quote